1 Introduction

Eco-Industrial Parks (EIPs) have emerged as a transformative approach for industries to collaborate, aiming to minimize waste, optimize value recovery, and achieve production efficiencies, (Tudor et al., 2007). Rooted in the principles of Industrial Ecology (IE) and Industrial Symbiosis (IS), EIPs envision industrial operations that mirror the cyclical and symbiotic relationships observed in natural ecosystems (Gibbs and Deutz, 2007). Defined by President’s Council for Sustainable Development (1996), an EIP is a collaborative community of businesses that share resources—including information, materials, water, energy, infrastructure, and natural habitats—resulting in economic, environmental, and social benefits.

The rapid economic growth in Africa, driven significantly by its industrial sector, underscores the continent’s increasing resource consumption. Yet, Africa grapples with environmental challenges, from climate-induced disasters to biodiversity loss (Jayaram et al., 2021). This juxtaposition has intensified the call for sustainable industrial practices, with stakeholders advocating for heightened environmental and social standards (van Beers et al., 2020).

Several African nations are recognizing the potential of EIPs. Initiatives to green industrial parks and policy frameworks supporting EIP transitions are evident across countries like South Africa, Kenya, Zimbabwe, and Egypt, among others (UNIDO, 2016). Notable EIP transitions, such as Ethiopia’s Hawassa industrial park (Negesa et al., 2022), and South Africa’s Limpopo eco-industrial park (Kathawaroo, 2018), highlight the continent’s evolving industrial landscape. However, comprehensive studies mapping Africa’s EIP distribution remain scant, with limited case studies evaluating their developmental potential.

Uganda, an economic frontrunner in East Africa, has earmarked 25 industrial parks for development, aligning with its Vision 2040 strategy (Goobi et al., 2017). With strategic frameworks like the National Development Plan III (Behuria, 2021) and the Green Recovery Action Plan (Uganda’ s Green Recovery Action Plan, 2021) in place, this study focuses on two Ugandan industrial parks—Kampala Industrial and Business Park (KIBP) and Mbale Industrial Park (MIP).

Therefore, to measure their development performance, we use the international framework for EIP (IF-EIP), developed by the World Bank Group (WBG) (United Nations Industrial Development Organization, 2017) which defines the evaluation indicators and minimum parameters for of park management, economic performance, environmental performance, and social performance of an EIP. We designed a questionnaire (Supplementary Table S1) using the framework indicators. This framework provides benchmarks for evaluating existing industrial parks to foster sustainable industrial growth in Uganda. Based on the results, a potential strategy for EIP development in Uganda is recommended.

This paper is organized as follows: Section 2, provides a literature review of industrial ecology, industrial symbiosis and comprehensive understanding of the EIP concept. In Section 3, the Methodology based on the International Framework for an Eco-Industrial Park (IF-EIP) as an assessment tool is explained. Section 4 presents the background of the case studies of KIBP and MIP in Uganda with details on industrial symbiosis in each park. Section 5 is the results and discussion of the performance assessment of the case studies, followed by the conclusion in Section 6.

2 Literature review

Industrial Ecology (IE) is an interdisciplinary field that integrates sustainability principles into environmental and economic systems. Drawing parallels with natural ecosystems, IE seeks to understand how industries can operate in harmony with their environment (Ehrenfeld and Gertler, 1997). As industries in Africa, particularly in Uganda, grapple with the challenges of rapid growth and environmental sustainability, the principles of IE offer a roadmap for harmonizing economic development with ecological preservation.

A subset of IE, Industrial Symbiosis (IS), emphasizes the mutualistic relationships among industries. It promotes collaborative resource management among geographically co-located firms, fostering industrial ecosystems where byproduct exchanges, utility sharing, and service sharing become the norm (Chertow, 2008). For countries like Uganda, with its burgeoning industrial sector, IS presents an opportunity to optimize resource utilization, reduce waste, and enhance economic competitiveness.

Building on IE and IS, the Eco-Industrial Park (EIP) concept envisions a community of industries collaborating for mutual benefit. EIPs can be greenfield projects or transformations of existing industrial parks into sustainable hubs (Lambert and Boons, 2002). The African continent, with its rapid industrial growth, stands to benefit immensely from EIPs. Notable examples include the Hawassa Industrial Park in Ethiopia (Negesa et al., 2022) and initiatives in Tanzania (Rweyendela and Mwegoha, 2021) and Nigeria (Ezeudu et al., 2021).

Globally, the EIP concept has gained traction, with countries across different continents adopting and adapting it (van Beers et al., 2020) assessed 50 industrial parks worldwide, offering insights that could guide Uganda’s EIP journey. The experiences from South Africa stand out as a pioneering initiative, being the first zero solid waste eco-industrial and integrated nature park in the country. With its comprehensive approach encompassing solar power, water storage, waste gasification, and eco-housing, LEIP serves as a model for sustainable industrial development (Kathawaroo, 2018). Additionally, the Gauteng Industrial Symbiosis Program (GISP), launched by the South African National Cleaner Production Center, emphasizes resource efficiency and waste minimization. This program has been instrumental in promoting sustainable industrial practices in Gauteng, South Africa’s leading industrial province (Oguntoye et al., 2019).

In the Southeastern part of Tanzania, the Kilembero Sugar Company Limited (KSCL) offers a glimpse into the potential of industrial symbiosis. The company, which is the largest sugar refinery in the Morogoro region, showcases a network of interconnected units sharing resources and exchanging wastes. The symbiotic relationships between these units highlight the potential for transforming KSCL into an EIP, given the right policy and regulatory environment (Rweyendela and Mwegoha, 2021). Kenya too has made strides in promoting sustainable industrial practices. The Kenya National Cleaner Production (KNCP) has been pivotal in assisting enterprises to adopt sustainable Consumption and Production practices. The country’s Green Economic Strategy and Implementation Plan (GESIP) for 2016–2030 further underscores its commitment to a low-carbon, resource-efficient, and inclusive socio-economic transformation. Studies by Khisa (2016) and (Khisa et al., 2018) delve into the potential of transforming Kenya’s economic zones into EIPs, emphasizing the need for a phased approach that prioritizes resource efficiency before waste and by-product exchange.

Uganda, with its strategic Vision 2040, is uniquely positioned to benefit from the EIP transformation. As the country seeks to bolster its industrial sector, the lessons from global and African EIP experiences can inform its strategy. The emphasis on sustainable industrial growth, coupled with the nation’s rich natural and human resources, presents an opportunity to create EIPs that are not just economically viable but also environmentally sustainable and socially inclusive.

The UNIDO framework for EIPs offers a structured approach to EIP development. By defining clear benchmarks and evaluation criteria, it provides a roadmap for countries like Uganda to assess, develop, and optimize their industrial parks. Given the research question of this manuscript, the UNIDO framework will serve as a critical tool in assessing the potential of KIBP and MIP in Uganda.

However, while frameworks and global experiences provide guidance, the success of EIPs in Uganda will hinge on localized strategies. Factors such as local ecosystems, industrial dynamics, stakeholder interests, and socio-cultural considerations will play a pivotal role. Therefore, an in-depth analysis of Ugandan context, understanding its unique challenges and opportunities, will be essential. Therefore, this study seeks to assess the development of KIBP and MIP against the UNIDO framework. By doing so, it aims to provide a baseline for sustainable industrial development in Uganda and offer policy recommendations.

3 Methodology

3.1 The international framework for eco-industrial park (IF-EIP)

Setting EIP standards and having an assessment tool are important for promoting EIP development. According to Pilouk and Koottatep (2017), several assessment tools are available, but they are all very similar, and their differences are only in their scale of assessment systems. For example, at the national level, China’s State Environmental Protection Administration (SEPA) set up a national standardized method to evaluate its EIPs (Geng et al., 2009). The indicators from this system though eco-efficient oriented did not address the essence of the EIP and have been recently improved upon (Huang et al., 2019) to strengthen the emphasis on the industrial symbiosis dimension in evaluating the EIPs. Several other regions also designed their own EIP criteria, including the Port of Cape Charles in the US, Italy, and Thailand and the eco-star criteria in Devens, Massachusetts (Côté and Liu, 2016). There is no internationally accepted standard for EIP (Van Berkel et al., 2009). With this absence of a replicable method and standards for EIPs, especially in developing African countries presently exploring industrial symbiosis in their parks (Mäkelä, 2017; Khisa et al., 2018; Madanhire et al., 2018), studies have found that “the lack of indicators has impeded the development of some parks as EIPs” (Veleva et al., 2016).

Three international organizations, the United Nations Industrial Development Organization (UNIDO), the World Bank Group and Gesellschaft für Internationale Zusammenarbeit GmbH (GIZ) (German Development Cooperation), worked together to publish an international framework for EIPs which defines the evaluation indicators and minimum parameters for environmental, social, economic and park management performance of an EIP. It is a specific framework as it outlines a common understanding of EIP concepts at an international level. Based on 51 criteria benchmarks, the framework outlines the basis for defining and setting prerequisites and performance requirements for EIPs (United Nations Industrial Development Organization, 2017). The EIP framework encourages industrial parks to exceed compliances and surpass the defined standards that fit the region. This is applied to the KIBP and MIP to provide assessment results and can further develop adaptable national standards.

3.2 IF-EIP criteria

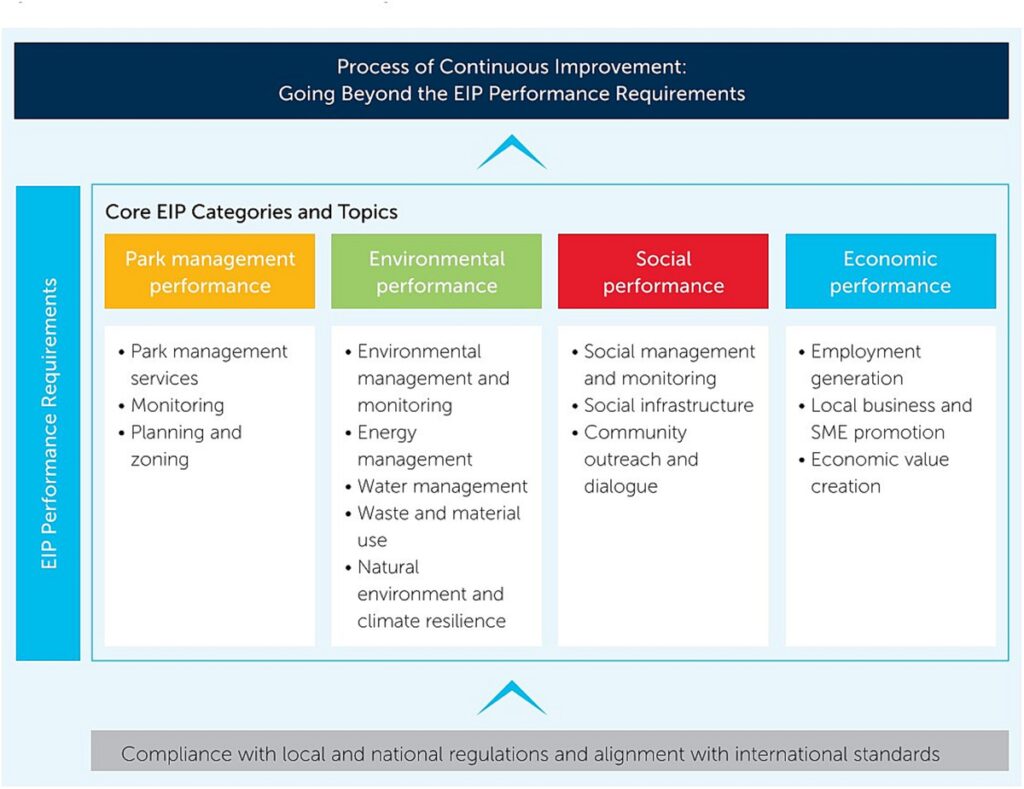

The IF-EIP delineates performance criteria across four pivotal categories, as illustrated in Figure 1. These categories encompass park management, economic, social, and environmental performance, each playing a crucial role in the holistic development and sustainability of an EIP.

3.2.1 Park management

Central to the success of any EIP is its management structure. A robust, formalized, and economically sustainable park management system can usher in myriad benefits, ensuring the smooth operation of the park and fostering a conducive environment for industries to thrive.

3.2.2 Environmental performance

This category underscores the importance of sustainable practices and the mitigation of potential environmental adversities. It emphasizes the adoption of low or zero-carbon energy generation methods and champions resource-efficient production processes. By prioritizing environmental performance, EIP can significantly reduce their ecological footprint, ensuring a harmonious coexistence with the environment.

3.2.3 Social performance

An EIP’s relationship with its surrounding community and its internal stakeholders is encapsulated in its social performance. This category advocates for the implementation of commendable social management practices, the promotion of decent work conditions, and the establishment of robust social and community infrastructures. By maintaining positive relations with the local community and adhering to international best practices, EIPs can foster a socially inclusive and harmonious environment.

3.2.4 Economic performance

Economic performance is pivotal for the viability and success of an EIP. Recognizing the role of these parks in bolstering the manufacturing sector and augmenting economic value, this category emphasizes the park’s contribution to the broader economic landscape. Governments often leverage an EIP as strategic tools to stimulate economic growth, drive innovation, and enhance the overall value proposition of their regions.

3.3 Data collection

This paper adopted a case study approach to understand and explain how the traditional industrial park can develop as EIPs. The case study approach is instrumental in elucidating the practical process and explaining the EIP practical process toward its development. Employing multiple cases strengthens the research foundation, allowing for cross-analysis comparison, and fostering a more reflexive interpretation through the discussions (Yin, 1994; Susur et al., 2019).

Uganda as one of the leading developing economies in East Africa was chosen as the empirical context. With its vision to develop 25 industrial parks by 2040 (Goobi et al., 2017), Uganda offers a rich ground for an insightful case study pertinent to the East African region. MIP, a relatively new industrial park developed in collaboration with a Chinese investor and KIBP was selected as the oldest industrial park wholly owned and developed by the Uganda government under the aegis of the Uganda Investment Authority see location in Figure 2.

Figure 2. Map of Uganda showing the location of the case studies. Source: Author.

Fieldwork for MIP and KIBP was conducted from May to August 2022, with additional field visits in September 2022. Semi-structured questionnaire interviews were held with senior and mid-level representatives from both parks. The secondary data encompassed public documents and specific reports. Table 1 summarizes both primary and secondary evidence, while Table 2 presents the performance metrics of KIBP and MIP.

Table 1. Source of primary and secondary evidence.

Table 2. Summary of KIBP and MIP’s performance indicators.

The questionnaire, detailed in Supplementary Table S1, was crafted based on the UNIDO framework’s indicators. To cater to region-specific nuances, this study incorporated an additional five environmental and three economic indicators. This resulted in a comprehensive list of 59 prerequisites and performance indicators spanning:

• Park Management Performance (6 prerequisites, 3 performance indicators): Park management services, monitoring, planning and designing;

• Economic Performance (4 prerequisites, 8 performance indicators): Employment generation, local business and SME promotion, and economic value creation;

• Social Performance (2 prerequisites, 11 performance indicators): Social management and monitoring, social infrastructure, and community outreach and dialogue;

• Environmental Performance (6 prerequisites, 19 performance indicators): Environmental management and monitoring, energy management, water management, waste and material use, and natural environment and climate resilience.

The distribution of questionnaires was facilitated through senior park managers who identified and recommended suitable industry managers and personnel to fill in the questionnaires. The decision to interview senior management was strategic; they not only possess comprehensive information about the parks but are also in a pivotal position to effect change or implement any methods for EIP development. The MIP manager recommended 10 personnel from the industries within the park, and 3 local government personnel who participated in the interview and Namanve Industrial Park’s senior park manager recommended 6 personnel from the industries within the park and 4 from the Uganda Investment Authority and 3 from the National Planning Authority and National Environmental Management Authority. Both managers comprised the interviewee, totalling 28 persons with 14 per park.

For this paper, the following assessment tool scoring was applied following the rating from the UNIDO framework (UNIDO, WBG, GIZ, 2021).

• Yes: Full compliance with the prerequisite/performance indicator;

• No: Non-compliance with the prerequisite/performance indicator;

• Partly: Partial compliance the prerequisite/performance indicator;

The semi-structured interviews, averaging 45 min each, were conducted in person and were recorded with the consent of the participants. Transcriptions were then analyzed manually. For the questionnaire data, a systematic approach was employed using Microsoft Excel. This tool, while seemingly basic, was chosen for its precision, flexibility, and robustness in handling data. Excel’s advanced data processing and analytical functions were utilized to categorize, filter, and derive patterns from the raw data. Pivot tables were employed to aggregate and cross-tabulate responses, ensuring a rigorous and comprehensive analysis to provide a clearer representation of the findings.

4 Case study background

4.1 Uganda context

Uganda is a landlocked country in the Eastern African region surrounded by the Democratic Republic of Congo, Kenya, Tanzania, Rwanda, and South Sudan. With a population of 47.2 million, Uganda is the world’s second most populous land-locked country after Ethiopia (World Population, 2022). Industrial parks are an integral part of Uganda’s industrialization strategy through its vision 2040, which seeks to achieve a “Transformed Uganda society from a peasant to modern and prosperous country within 30 years” (Uganda Investment Authority, 2021).

Uganda developed its first National Industrial Policy in February 2008 to provide strategic direction for industrialization. The overall vision of the policy was to build the industrial sector into a modern, competitive and dynamic industry, fully integrated with domestic, regional and global economies (Goobi et al., 2017). After a decade of implementation, a review was undertaken in 2017. The findings and recommendations from the review process informed the drafting of the National Industrial Policy, which serves as a blueprint for Uganda’s industrial transformation over 2020–2030. This policy has been aligned with the National Development Plan III, Vision 2040, East African Community Vision 2050, Africa Agenda 2063, the Sustainable Development Goals (SDGs) and the current trends in industrialization within the region and globally (Ministry of Trade Industry and Cooperatives, 2020). The specific objectives of the National Industrial Policy are to increase public investment and to nurture industrial development projects in strategic areas; increase and sustain the supply of quality raw materials for value addition; develop and strengthen skilled human resources to increase productivity and efficiency in the sector; accelerate development; use of research innovations and adoption of appropriate technologies in the industry; promote resource-efficient and environmentally sustainable industrialization (Goobi, 2021).

The Uganda Investment Authority develops the Industrial Parks in Uganda. This authority has set out five strategic goals, which are to promote Uganda as the preferred foreign direct investment destination; promote domestic investment and innovation; improve domestic and international competitiveness and doing business rankings through an efficient One Stop Center; accelerate Uganda’s industrialization through serviced industrial parks, and enhance institutional capacity to deliver its mandate (Uganda Investment Authority, 2021).

At the time of this study, the Government of Uganda demonstrated a renewed interest in proactive industrial policy with a clear sense of industrialization strategies, including a National Industrial Policy and an industrialization masterplan (Walter et al., 2020). During his State of the Nation Address delivered in June 2019, President Yoweri Museveni stated, “Government is prioritizing investment in Industrial Parks to support industrialization and create jobs” (Goobi, 2021). So far, there are already 284 new factories in the Industrial Park at Namanve, 11 in Luzira Industrial and Business Park, 10 in Bweyogerere Industrial Estate, eight in Jinja Industrial and Business Park, 10 in Soroti Industrial and Business Park, 16 in Kasese Industrial and Business Park, and 42 in Mbarara SME Park with a total number of factories in Uganda today as 4,900 (Uganda Investment Authority, 2021). A detailed list of these industrial parks, including the current status, potential targeted sectors, and expected number of jobs to be created, is shown in Supplementary Table S2.

4.2 Industrial symbiosis KIBP

KIBP is an approximately 890 hectares park located 11 km on the Kampala-Jinja highway and is the largest of the industrial parks currently in operation in Uganda (Macdonald, 2019). Presently, 71 companies have been established in KIBP, and another 146 firms are under construction and at various development stages, with another total of 336 expected to be located in the park (Goobi, 2021). The majority of the industries in KIBP are manufacturing industries focused on textile, agro-processing, plastic processing, etc.

4.2.1 By-products and waste management

The current state of waste management in the Namanve Industrial Park is characterized by individualized waste disposal methods. Previously, attempted waste treatment method known as the Rootzone Filter System, which was designed to minimize waste, cut pollution, and promote an eco-friendly approach to waste management. However, this method was not universally accepted by factory owners and was eventually dropped. Each of the 71 operational industries within the park is responsible for managing its own waste disposal. This has led to a lack of homogeneity in waste collection and management across the park. However, the government has recognized the need for a centralized waste management system and has contracted a consortium to supervise the construction of such a facility. This facility, which will be located in the southern part of the park, will serve as a waste transfer and sorting station. It will handle solid waste, hazardous/toxic waste, and organic waste, which will be composted on-site. Despite these advancements, the park still faces challenges such as unauthorized waste dumping and potential risks to nearby wetlands and woodlands due to inappropriate disposal of construction waste and litter. Moreover, the park’s Solid Waste Management Strategy (SWMS) outlines a robust plan for managing waste arising on-site. This strategy involves the collection of waste from occupants, separation of waste into different types (solid, hazardous/toxic, and organic) at the proposed solid waste facility, and subsequent transfer to the National Management and Authority approved waste contractors off-site. The strategy also includes on-site composting of organic waste.

4.2.2 Water supply and drainage system

KIBP nestled within the Lake Victoria drainage basin, inherently prioritizes its water supply and drainage management. The park’s topography, marked by the Namanve River’s presence and a predominant southward gradient, dictates water flow patterns and introduces distinct water management challenges (Angiro et al., 2020). Presently, the park confronts flooding issues, especially around the Namanve River, and the repercussions of effluent discharge on water dynamics. These problems are exacerbated by illicit sand mining and unauthorized waste disposal activities, jeopardizing the water and drainage systems. In response, KIBP is advancing a robust water and drainage infrastructure. Spearheaded by the Uganda Investment Authority, a dedicated facility is being established (Macdonald, 2019). This center will oversee the pre-treatment and segregation of industrial waste before its integration into the system. The infrastructure is designed to encompass both solid waste management and a specialized liquid waste system for radioactive waste, underscoring a comprehensive waste management strategy.

The current 250 mm transmission main, stretching along the Kampala Jinja Road, was designed to cater to the South A & B estates of KIBP and Coca-Cola, with capacities of 7,100 m3/day and 1,400 m3/day, respectively. To bolster supply, a new 500 mm trunk main, extending from the Mutungo Hill Reservoir to Jinja Road, has been installed. This main is equipped to meet the entire water demand of both KIBP and the Coca-Cola factory. A connection from this main currently powers a booster pump station, channeling water to the Namilyango hill tank. Notably, the post-completion scenario of the Gaba III water treatment plant in Kampala has enhanced the water system, ensuring the park’s future water demands are met without hindrances. For sustained water supply, one strategy involves leveraging the connection from the existing transmission main along the Kampala-Jinja Road. This connection can feed a new reservoir at Buto Hill, ensuring water supply to North, South A, and South B. This reservoir’s construction is envisioned in two phases, aligning with KIBP’s developmental trajectory. A long-term alternative, contingent on the upcoming Katosi water plant, might render the booster pumps and reservoir redundant at the park’s peak consumption. However, this proposition warrants further investigation during the detailed design phase.

4.2.3 Renewable hydroelectric energy

The KIBP is making significant strides in the realm of sustainable energy by harnessing renewable hydroelectric power for its operations. The park is equipped with a robust hydroelectric power infrastructure, ensuring a reliable and consistent supply of electricity to all its occupants. This infrastructure includes high voltage substations and transmission lines, a project initiated in 2016 by the Uganda Electricity Transmission Company Limited (UETCL). The primary goal of this initiative is to provide industrialists with a stable electricity supply, thereby stimulating consumption and promoting efficient operations. The Namanve substation is a testament to the park’s commitment to renewable energy. It houses three transformers, each with the capacity to handle 70 MW, demonstrating the park’s ability to cater to high energy demands. Furthermore, the park is served by an 11-kilometer 33KV 3-phase power line, providing coverage to approximately 24 percent of the park. However, it’s important to note that while the current infrastructure is commendable, there is room for improvement. The existing power line coverage only reaches a quarter of the park, indicating a need for expansion to ensure all industries within the park can benefit from this renewable energy source. Additionally, the integration of other renewable energy sources, such as solar or wind, could further enhance the park’s sustainability and resilience.

4.2.4 Service sharing

Service infrastructure: – Potable water supply – Waste water treatment plant and associated sewage pipes – Solid waste processing – Power supply – Telecommunications – Facilities for small and medium-sized enterprises. The KIBP infrastructure requires an independent telecommunication network that can serve as a platform for multiple services across all industries and services. This network will be connected to the wider fiber optic cabling, which falls under the responsibility of the Ugandan Ministry of Information and Communication Technology (ICT), at a connection point on Jinja Road. To ensure high-speed Internet and telephone access within the KIBP, the proposed scheme suggests having a minimum of two ducts per access route, with the possibility of increasing this number. Furthermore, a dedicated fiber route will be evaluated specifically for the KIBP, with a focus on areas that house commercial and SME industries. Additionally, telecom facilities will be established and managed, primarily in the center of Sector South B. This will enable external connections through cables or satellite, as well as monitoring of the internal telecom network once it is installed.

4.3 Industrial symbiosis in MIP

MIP is approximately 619 hectares, built and operated by the Uganda Tiantang Group in Mbale, Eastern Uganda. The industrial park is one of the state-level industrial parks in Uganda, with support from both the governments of China and Uganda. The park comprises of 24 industries; however, only 13 are operational due to issues resulting from the outbreak of the COVID -19 pandemic (Tian Tang Group, 2022). The majority of the industries in MIP are manufacturing companies focused on textiles, steel construction, personal care, etc.

4.3.1 By-products and waste management

The MIP, a confluence of diverse industrial sectors, offers a plethora of opportunities for the implementation of industrial symbiosis through by-product exchange and efficient waste management. For instance, Ubon Personal Care, engaged in the manufacturing of personal care products, could potentially generate glycerine as a by-product. This glycerine, rather than being discarded, could serve as a valuable raw material for other industries within the park, particularly those involved in the production of soaps, detergents, or similar personal care products. In a similar vein, Duby Max Electronics Uganda Limited, an entity involved in electronics manufacturing, could produce electronic waste that, upon recycling, could yield recovered metals such as copper and precious metals. These recovered materials could then be utilized by other industries for the manufacturing of new electronic components.

Honor Emblem, a manufacturer of steel structures, could produce steel scrap that, if recycled, could be repurposed by other industries requiring steel as a raw material. Sunshine Food, a food processing company, could generate organic waste that could be repurposed for composting or used as a feedstock for bioenergy production. In the textile sector, entities such as Grace Form Limited and the textiles companies could recycle textile waste for the production of new textiles or other products. Z.H.Y, a manufacturer of cement brick products, could utilize waste from cement production, such as fly ash or slag, in the production of concrete or other construction materials.

However, it is noteworthy that the Glass Processing company, despite its potential to recycle glass waste for the production of new glass products, currently appears to outsource its waste to a recycling company in town. This suggests a lack of symbiosis within the park and underscores the need for a more integrated approach to waste management and by-product exchange within the park. Such an approach would not only promote the principles of the circular economy but also enhance the overall sustainability of the industrial park.

4.3.2 Water supply and drainage system

At the time of this research, the park, situated near a wetland in Mbale City, suffered significant infrastructural damage and loss of life due to a catastrophic flood event in July 2022 (Kimeu, 2022). This disaster (Figure 3) underscored the park’s existing issues with water supply and drainage systems, exacerbated by rapid development without adequate water management strategies. To mitigate future risks, it is imperative to develop robust water management systems, including effective drainage to manage heavy rainfall and reliable water supply for the park’s industries. These systems must be designed with respect for the surrounding wetland’s ecological integrity, necessitating careful planning and sustainable practices. Moreover, comprehensive disaster management strategies are crucial. These should encompass early warning systems, emergency response plans, and disaster response training for park personnel and local communities. The flood event highlighted the urgent need for robust water management and disaster response strategies within the Sino-Mbale Industrial Park, crucial for its sustainable development and the safety of the wider Mbale City region.

Figure 3. Mbale industrial park factory flooding. Source: Author.

4.3.3 Renewable hydroelectric energy

The park has faced challenges with its power supply. The Minister of Energy, Ruth Nakabirwa, installed a mobile power substation by UETCL to address this issue. Despite these efforts, the power supply remains inadequate, with a capacity of only 240 MW (Christine, 2021). This has implications for the park’s ability to achieve its production and export targets, and may affect the operations of the various industries located within the park. Efforts are ongoing to improve the power infrastructure and ensure a reliable supply of energy to the park.

4.3.4 Service sharing

The park employs a shared infrastructure system that is instrumental in supporting the operations of all resident industries. A cornerstone of this shared infrastructure is the Luban Workshop, a vocational training facility that equips workers from various industries within the park and the local community with essential skills (Liu and Dai, 2021). The workshop houses four professional training rooms, including an electrical automation technology training center, a machine training center, an industrial simulation training room, and an engineering practice innovation training room. Additionally, four professional training areas are dedicated to teaching the discipline of ferrous metallurgy. Complementing the educational infrastructure, the park also boasts a mobile power substation, installed by the Uganda Electricity Transmission Company Limited (UETCL). This substation provides a stable and reliable power supply to all industries within the park, facilitating efficient and uninterrupted operations. Moreover, the park has established a basic shared waste management system, contracting a waste collection company to manage waste from all industries within the park. This shared service ensures systematic and environmentally friendly waste management, underscoring the park’s commitment to sustainable industrial development. The shared infrastructure system not only provides essential services but also fosters a sense of community within the park, allowing industries to focus on their core operations while benefiting from shared services.

5 Results and discussion

5.1 Case analysis with the international framework for an EIP

The framework for an EIP discussed in the methodology sets specific requirements for industrial parks. The assessment results show that both parks meet 26 indicators with KIBP (6 park management, 6 economic, 5 social and 9 environmental) and MIP (6 park management, 6 economic, 9 social and 5 environmental). Figure 4 shows the prerequisites and indicator performance results of both parks.

Figure 4. The total number of indicators KIBP and MIP meet compared to the UNIDO framework standards. Source: Author.

5.1.1 Park management performance

KIBP has a park master plan, whereas MIP does not, but both parks have a management entity that handles park planning, operations and monitoring. For KIBP, the monitoring is done but not so effective as the Freezone only monitors job creation, and the National Environmental Management Authority monitors environmental issues. Both parks have a functioning system in place to comply with local, national and international standards applicable to the industrial parks.

5.1.2 Economic performance

The economic indicators in both parks have shown that the parks create employment, with Namanve reportedly employing 15,000 Ugandans in the park (Manwaring, 2021). The MIP has set up a technical vocational education training center called the Luban workshop that provides technical skills to its employees and community members (Tian Tang Group, 2022).

5.1.3 Social performance

KIBP and MIP have dedicated personnel to plan, manage and enforce social standards in the park. The results show that both parks have equality in work for both men and women, where they agree that decent work criteria are met. However, both are not satisfied with the park’s efforts to timely respond to safety issues and general efforts to communicate. There is a need to review the actual practices for both industrial parks.

5.1.4 Environmental performance

KIBP and MIP’s majority of environmental indicators are not met especially having an appropriate functioning environmental management system. Both parks leverage available renewable generation sources like solar and biomass. KIBP has environmental regulations but still much noncompliance; it has set up energy efficiency strategies with development partners like the National Environment Management Authority. There are considerable efforts by the Global Green Growth Institute, the Ministry of Energy and the World Bank to support programs to improve the energy efficiency of resident firms in KIBP.

6 Discussion

EIPs are important infrastructure and provide the catalysts for industrial ecology development. The insights from KIBP and MIP underscore the imperative of fostering collaboration among government officials, businesses, and communities through educational initiatives tailored for eco-industrial development. A SWOT analysis in Table 3, informed by literature and interview feedback, elucidates the potential of these parks to develop as EIPs with the active involvement of key stakeholders.

Table 3. SWOT analysis for the development of an EIP in Uganda.

6.1 The role of the government

Uganda has formally committed to the National Industrial Policy, which serves as a blueprint for Uganda’s industrial transformation over 2020–2030. The National Environmental Management Authority, Uganda Investment Authority and other governmental authorities are powerful stakeholders in this commitment and play key roles in promoting the development through such aspects as decision-making, creating policies, issuing laws and regulations, organizing pilot activities, providing financial incentives encouraging innovations in technology and systems, fostering new markets and promoting both education and academic research partnerships.

6.1.1 The role of enterprises

In order to promote and cultivate an effective industrial symbiosis, it is crucial for the industries involved to possess diversity and complement each other in terms of their production and utilization of materials. One or more anchor tenants: EIP can be a success if it depends on the anchor firm, which can bring together the existing industries by creating links built by the by-products around them. To develop a successful by-product synergy, there must be a close geographic proximity between the industrial partners to enable adequate transportation of materials (Chertow, 2000). The anchor tenant would work as a mediator to endorse the idea of collaboration in terms of services, water and energy from the relevant industries (Hewes, 2005).

6.1.2 International cooperation

One of the interviewees stated that significant support and cooperation from national and international agencies for projects related to cleaner technologies, green economy, sustainable development and environmental management is one of the features of Uganda’s industrialization strategy. An institutional network has been formed through organizations like the Global Green Growth Institute and the Uganda Cleaner Production Center (Global Green Growth Institute, 2022). In 2022, the Ministry of Finance, Planning and Economic Development (MoFPED), the Ministry of Water and Environment (MWE), and the National Planning Authority (NPA) signed a commitment with development partners; GIZ Uganda, the United Nations Framework Convention on Climate Change (UNFCCC) Regional Collaboration Center (RCC) and the Global Green Growth Institute (GGGI) to support Uganda’s economic green growth objectives and to implement several green projects ranging from climate-smart agriculture to greening Uganda’s cities and industrial sectors (Zwebe, 2022).

6.1.3 Financial support

Financial support can play an important role in the development of EIPs as they can provide support for businesses and industries to adopt sustainable practices and technologies. This support can be used to encourage investment in EIP development, promote the adoption of green technologies, and support sustainable production and consumption practices. For the case of MIP, this financial support can provide the community with opportunity to afford waste sorting bins, waste sorting system to clean the city as an initial step to waste management. Thought must therefore be given to creating financial support that will maximize benefits and ensure that these are shared by all involved. Similar suggestions have been made by a study of Geme et al. (2023), which highlighted that financial support is crucial in order to adopt circular practices among businesses in Uganda. Also, financial support could encourage business to adopt the CE by promoting smart services which could trigger innovation driven growth and efficient resource use (Suzic et al., 2022).

6.1.4 The role of the community

The role of the community in EIP development can be significant, as it can help to ensure that the park meets the needs of the local community and that it is sustainable in the long term. One of the key ways in which the community can contribute to EIP development is through the participation in the planning and decision-making processes. This can involve community engagement and consultation sessions where community members can provide feedback and input on the proposed EIP development. Community members can also be involved in the development of specific projects within the EIP, such as renewable energy or waste management initiatives.

Another way in which the community can play a role in EIP development is through the promotion of sustainable consumption and production practices. This can involve educating the community on the benefits of EIPs and sustainable production practices, and encouraging the use of sustainable products and services that are produced within the EIP. The community can also contribute to the monitoring and evaluation of the EIP’s performance. This can involve monitoring the environmental and social impacts of the EIP, and providing feedback to the park managers on areas that require improvement. Furthermore, the community can also benefit from EIP development, as it can provide new employment opportunities and stimulate local economic development.

In order for the community to play an effective role in EIP development, it is important for park managers to establish effective communication channels and engagement strategies. This can involve developing partnerships with community organizations, hosting community events and workshops, and providing regular updates on the park’s performance and initiatives. The involvement of the community in EIP development can have a significant impact on the success and sustainability of the park. By engaging with the community, EIP managers can ensure that the park meets the needs of the local community and contributes to the long-term sustainable development of the region.

6.1.5 Education and research

Different components, especially local institutions and research centers, play significant roles in investigating various industrial ecology issues that contribute to EIP development. The Uganda Cleaner Production Center supports the promotion of industrial ecology; however, academic research on EIP development is still in its infancy. A study by Nijman-Ross et al. (2023) also emphasized the crucial role of circular economy research for African countries, especially with the private sector and industries to adopt circular practices and innovation. Furthermore, this study suggests integrating industrial ecology and circular economy in the curriculum is necessary for providing practical tools for eco-industrial park development to become mainstream in Uganda and Africa. A similar suggestion has been made by study of Geme et al. (2023) which emphasized the role of education on the level of knowledge on the circular economy among stakeholders in Uganda.

7 Limitations

This study was conducted with the aim of providing comprehensive insights into the potential for eco-industrial park development in Uganda. However, there are several:

1. Sample size and scope: The study is based on interviews with a limited number of participants from MIP and KIBP. While these participants provided valuable insights, they represent a small fraction of the potential stakeholders in EIP development. This limitation in the diversity and number of participants may affect the generalizability of the findings.

2. Geographical constraints: The research focused on industrial parks in only two specific regions of Uganda. Different regions in the country may have varying environmental, economic, and social conditions that were not accounted for in this study, potentially limiting the applicability of the findings to all regions.

3. Data collection: The data was collected using semi-structured interviews, which, while valuable for in-depth insights, rely on the subjective experiences and opinions of the respondents. There may be inherent biases or perspectives that could influence the responses, and the findings may not encompass all potential aspects of the issue.

4. Temporal factors: This study represents a snapshot in time, and the dynamics of industrial parks and environmental considerations are subject to change. Ongoing developments in policy, technology, and economic conditions might influence the future landscape of eco-industrial park development, which this study may not account for.

Acknowledging these limitations, the findings of this study provide a foundational understanding of the current landscape of EIP development in Uganda and highlight potential areas for future research and policy development.

8 Conclusion

This paper underscores the nascent stage of EIPs evolution within the African context, particularly Uganda, highlighting the critical role of a multi-stakeholder engagement and the alignment of economic gains with sustainable practices. The transformation into EIPs represents a strategic pivot toward sustainable industrialization, requiring concerted efforts from various sectors.

Key recommendations emerging from this study include:

1. Policy integration and incentivization: The government should articulate clear, supportive policies that incentivize eco-industrial initiatives. These policies must encompass financial incentives, technical support, and a regulatory framework that encourages waste reduction, resource efficiency, and sustainable industrial practices.

2. Capacity building and education: There is an urgent need to bolster academic research and educational programs in industrial ecology. Enhancing the capacity of local institutions and the workforce through training and development programs will underpin the successful transition to EIPs.

3. Community engagement and public-private partnerships: Active involvement of the local community and the establishment of robust public-private partnerships are essential. These collaborative approaches ensure the alignment of EIPs with community needs, fostering social acceptance, and promoting shared responsibility.

4. Customized eco-industrial solutions: Recognizing the unique economic, social, and environmental context of Uganda, EIP strategies should be tailored to local conditions. This customization involves developing region-specific indicators for EIP evaluation and integrating local environmental and economic objectives.

5. Pilot projects and scalable models: Uganda should consider initiating pilot projects, such as the proposed EIP in Mbale, to test, refine, and demonstrate the viability of eco-industrial models. Successful pilots will serve as scalable models for other regions, providing practical insights and momentum for nationwide EIP initiatives.

By embracing these strategies, Uganda can forge a path toward sustainable industrial development, balancing economic growth with environmental stewardship and social well-being. The journey toward fully realized EIPs may be complex, but the long-term benefits for the nation’s economy, environment, and communities justify the investment and effort required.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

DN: Conceptualization, Investigation, Writing – original draft, Writing – review & editing. TG: Writing – review & editing, Formal analysis. EN-R: Writing – review & editing, Supervision. EN: Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This research was made possible by the support received from MAVA Foundation through their contribution to the African Leadership University Circular Economy Programme.

Acknowledgments

The authors would like to express sincere gratitude to the MAVA foundation for providing us with the opportunity to carry out this research, Elinah Manashe for Mbale Industrial Park, Andrew Muwaza for Namanve Industrial Park and to the students Winifred Awinpoya Atanga and Tshepiso Masilonyane from African Leadership University for their assistance in compiling material for the study.

Conflict of interest

The authors declare that the research was conducted without any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2023.1286611/full#supplementary-material

References

Angiro, C., Abila, P. P. O., and Omara, T. (2020). Effects of industrial effluents on the quality of water in Namanve stream, Kampala industrial and Business Park, Uganda. BMC Res. Notes 13:220. doi: 10.1186/s13104-020-05061-x

PubMed Abstract | CrossRef Full Text | Google Scholar

Behuria, P. (2021). The political economy of reviving industrial policy in Uganda. Oxford Dev. Stud. 49, 368–385. doi: 10.1080/13600818.2021.1960296

CrossRef Full Text | Google Scholar

Chertow, M. R. (2000). Industrial symbiosis: literature and taxonomy. Annu. Rev. Energy Environ. 25, 313–337. doi: 10.1146/annurev.energy.25.1.313

CrossRef Full Text | Google Scholar

Côté, R., and Liu, Z. (2016). Eco-Industrial Park performance standards and indicators and the circular economy. Dalhousie University. Devens, Massachusetts.

Google Scholar

Ehrenfeld, J., and Gertler, N. (1997). Industrial ecology in practice: the evolution of interdependence at kalundborg. J. Ind. Ecol. 1, 67–79. doi: 10.1162/jiec.1997.1.1.67

CrossRef Full Text | Google Scholar

Ezeudu, O. B., Oraelosi, T. C., Agunwamba, J. C., and Ugochukwu, U. C. (2021). Co-production in solid waste management: analyses of emerging cases and implications for circular economy in Nigeria. Environ. Sci. Pollut. Res. 28, 52392–52404. doi: 10.1007/s11356-021-14471-8

PubMed Abstract | CrossRef Full Text | Google Scholar

Geme, T., Nijman, E., Ntawuhiganayo, E. B., and Negesa, D. (2023). Stakeholder knowledge and perceptions of the circular economy in Ugandan cities. Front. Sustain. 4:1117814. doi: 10.3389/frsus.2023.1117814

CrossRef Full Text | Google Scholar

Geng, Y., Zhang, P., Côté, R. P., and Fujita, T. (2009). Assessment of the national eco-industrial park standard for promoting industrial symbiosis in China. J. Ind. Ecol. 13, 15–26. doi: 10.1111/j.1530-9290.2008.00071.x

CrossRef Full Text | Google Scholar

Gibbs, D., and Deutz, P. (2007). Reflections on implementing industrial ecology through eco-industrial park development. J. Clean. Prod. 15, 1683–1695. doi: 10.1016/j.jclepro.2007.02.003

CrossRef Full Text | Google Scholar

Goobi, R. (2021). Skills for industry. European Commission. Luxembourg.

Google Scholar

Goobi, R., Wabukala, B. M., and Ntayi, J. (2017). Economic development and industrial policy in Uganda. Germany: Friedrich-Ebert-Stiftung.

Google Scholar

Hewes, A. K. (2005). The role of champions in establishing eco industrial parks. UMI. Ann Arbor, MI

Google Scholar

Huang, B., Yong, G., Zhao, J., Domenech, T., Liu, Z., Chiu, S. F., et al. (2019). Review of the development of China’s eco-industrial park standard system. Resour. Conserv. Recycl. 140, 137–144. doi: 10.1016/j.resconrec.2018.09.013

CrossRef Full Text | Google Scholar

Kathawaroo, D. (2018). Limpopo eco-industrial park. Vancouver, Canada.

Google Scholar

Khisa, K., Oguge, N., and Obiero, S. A. (2018). Mainstreaming the culture of eco-industrial parks (EIPs) in Kenya for the sustainable realization of the Country’s vision 2030. J. Int. Bus. Res. Mark. 3, 7–21. doi: 10.18775/jibrm.1849-8558.2015.36.3001

CrossRef Full Text | Google Scholar

Kimeu, C. (2022). At least 24 people dead as flash flooding hits eastern Uganda. Ethan Freedman Climate Reporter. New York.

Google Scholar

Lambert, A. J. D., and Boons, F. A. (2002). Eco-industrial parks: stimulating sustainable development in mixed industrial parks. Technovation 22, 471–484. doi: 10.1016/S0166-4972(01)00040-2

CrossRef Full Text | Google Scholar

Liu, Y., and Dai, Y. (2021). A study on China-Africa vocational education cooperation. Tianjin Publishing and Media Group

Google Scholar

Macdonald, M. (2019). Kampala industrial and business park infrastructure scheme ESIA volume II: Main ESIA report. Kampala, Uganda.

Google Scholar

Mäkelä, Albert (2017). Circular economy SWOT analysis in South-Africa, Bachelor‟s Thesis in energy technology. Botswana and Namibia.

Google Scholar

Ministry of Trade Industry and Cooperatives (2020). National industrial policy: a framework for Uganda’s industrialization, employment and wealth creation. Kampala, Uganda.

Google Scholar

Negesa, D., Cong, W., Cheng, L., and Shi, L. (2022). Development of eco-industrial parks in Ethiopia: the case of Hawassa Industrial Park. J. Ind. Ecol. 26, 1078–1093. doi: 10.1111/jiec.13247

CrossRef Full Text | Google Scholar

Nijman-Ross, E., Umutesi, J. U., Turay, J., Shamavu, D., Atanga, W. A., and Ross, D. L. (2023). Toward a preliminary research agenda for the circular economy adoption in Africa. Front. Sustain. 4:1061563. doi: 10.3389/frsus.2023.1061563

CrossRef Full Text | Google Scholar

Oguntoye, O., Geissdoerfer, M., Nuwarinda, H., and Evans, S. (2019). Facilitating industrial symbiosis programmes in developing countries: reflections from Gauteng, South Africa. Dev. Pract. 29, 115–121. doi: 10.1080/09614524.2018.1527289

CrossRef Full Text | Google Scholar

Pilouk, S., and Koottatep, T. (2017). Environmental performance indicators as the key for eco-industrial parks in Thailand. J. Clean. Prod. 156, 614–623. doi: 10.1016/j.jclepro.2017.04.076

CrossRef Full Text | Google Scholar

President’s Council for Sustainable Development. (1996). Eco-industrial park workshop proceedings. President’s Council for Sustainable Development, Washington.

Google Scholar

Rweyendela, A. G., and Mwegoha, W. J. S. (2021). Industrial symbiosis in Tanzania: a case study from the sugar industry. African J. Sci. Technol. Innov. Dev. 13, 595–606. doi: 10.1080/20421338.2020.1773605

CrossRef Full Text | Google Scholar

Susur, E., Martin-Carrillo, D., Chiaroni, D., and Hidalgo, A. (2019). Unfolding eco-industrial parks through niche experimentation: insights from three Italian cases. J. Clean. Prod. 239:118069. doi: 10.1016/j.jclepro.2019.118069

CrossRef Full Text | Google Scholar

Suzic, B., Urban, S., Hellwig, M., and Dobler, M. (2022). “Smart circular economy value drivers: The role of the financial sector in stimulating smart regional innovation-driven growth,” Springer, Cham

Google Scholar

Tian Tang Group (2022). Sino-Uganda Mbale industrial park. Tian Tang Group. Uganda

Google Scholar

Tudor, T., Adam, E., and Bates, M. (2007). Drivers and limitations for the successful development and functioning of EIPs (eco-industrial parks): a literature review. Ecol. Econ. 61, 199–207. doi: 10.1016/j.ecolecon.2006.10.010

CrossRef Full Text | Google Scholar

Uganda Investment Authority (2021). Status of industrial and business parks and agricultural lands in Uganda. Industrial and business parks: Kampala

Google Scholar

Uganda’ s Green Recovery Action Plan. African Union Green Recovery Action Plan (2021). Sustainable Environment and Blue Economy. Addis Ababa, Ethiopia

Google Scholar

UNIDO (2016). Global assessment of eco-industrial parks in developing and emerging countries: achievements, good practices and lessons learned from thirty-three industrial parks in twelve selected emerging and developing countries. UNIDO. Vienna, Austria

Google Scholar

UNIDO, WBG, GIZ (2021). International framework for eco-industrial parks. UNIDO, WBG, GIZ. Washington, DC.

Google Scholar

United Nations Industrial Development Organization (2017). An international framework for eco-industrial parks. United Nations Industrial Development Organization. Veinna

Google Scholar

van Beers, D., Tyrkko, K., Flammini, A., Barahona, C., and Susan, C. (2020). Results and lessons learned from assessing 50 industrial parks in eight countries against the international framework for eco-industrial parks. Sustainability 12, 1–33. doi: 10.3390/su122410611

CrossRef Full Text | Google Scholar

Van Berkel, R., Fujita, T., Hashimoto, S., and Geng, Y. (2009). Industrial and urban symbiosis in Japan: analysis of the eco-town program 1997–2006. J. Environ. Manag. 90, 1544–1556. doi: 10.1016/j.jenvman.2008.11.010

PubMed Abstract | CrossRef Full Text | Google Scholar

Veleva, V., Lowitt, P., Angus, N., and Neely, D. (2016). Benchmarking eco-industrial park development: the case of Devens. Benchmarking Int. J. 23, 1147–1170. doi: 10.1108/BIJ-06-2014-0056

CrossRef Full Text | Google Scholar

Yin, R. K. (1994). “Case study research: design and methods, applied social research methods series” in Essential guide to qualitative methods in organizational research. eds. S. Cassell and G. Symon (California: Sage Publications).

Google Scholar

Source link : https://www.frontiersin.org/journals/sustainability/articles/10.3389/frsus.2023.1286611/full

Author :

Publish date : 2023-11-27 08:00:00

Copyright for syndicated content belongs to the linked Source.